Over the last 40 Years, Farmgard has been supplying & distributing agriculture machinery, farm equipment & machinery in New Zealand. For more info contact us.

Wednesday, 9 February 2022

Tips for Buying a Slurry Applicator

How to Buy the Right Mower

Lawn mower types:

Cylinder

Rotary

Hover

Lawnmower power options:

Electric lawnmowers:

Cordless lawnmowers

Petrol lawnmowers

Push lawn mowers

Wednesday, 29 December 2021

Buying Guide for Harrows

Harrows NZ-wide is used to break up dirt and flatten the surface in preparation for planting or after ploughing. Choosing the appropriate harrow requires determining what conditions will be handled as well as the equipment that will be utilised in combination with this tool. There are a few different sorts of harrows: disc models, tine models, and drag chain models are the most prevalent. Each is suitable for a distinct type of job.

What to consider when buying the right harrow for your application:

Cultivation:

The flexible Stump Jump Harrow is the

secondary tillage equipment to consider if your land is uneven, rough cleaned,

or contains light stony parts. The floating stump jump motion is a tried and

true agricultural implement made of high carbon steel. Suitable for breaking

down clods, final seed preparation of the land, and levelling heavy pasture

area that has been plugged up or packed down. Stump Jumps are also great for

weed control and the preparatory stage of vegetable production.

To ensure true tracking and correct

stump-jump movement, each Stump Jump segment is attached to the drawbar by four

hitching points – one ahead of each row of tines.

Abbey Diamond harrows are a good choice for

wide terrain and lighter loamy soils, and they're a good tool for weed

management and seedbed preparation. It will give your crops every chance by

cracking soil crusts and permitting enhanced aeration and moisture penetration.

Leveling

In addition to sowing or cultivating

instruments, levelling harrows are a good choice. The flexible frame design

provides durability in various soil types and is designed to level soil and

seedbeds. In light to medium soils, 3 and 4 rank versions are ideal for use

with combines and seed drills to cover seed. In heavy soils, the 5 rank model

is utilised to combat weed development and break down huge clods. It's a

popular tool that goes well with cultivators and scarifiers.

The 'Extra Heavy' Leveling Power Harrow is a good alternative if you want to level your land and require a harrow that can withstand the demands of today's conditions. Each tine is made of high carbon steel and has been specifically forged to expose a diamond form that will help you level your ground. Tine spacing is the same as the regular form, making it particularly ideal for heavier clay soils and for usage after primary or secondary irrigation.

Pasture

For pasture establishment, management, and renewal, the Pastureland Harrow System is recommended. Using this equipment will boost pasture growth by breaking down and distributing animal manures and other organic waste uniformly across the entire pasture. This light duty harrow is best for pastures under 100 acres (40 hectares) and tows readily behind small and medium tractors.Four rows of double-sided tripod tine

units are used to cut through manure, clods, and coarse vegetation. The hefty

steel square chain mesh that follows the tripod portion further pulverizes and

spreads the manure and organic particles, revitalizing the pasture. The

"regular" single-mesh chain has eight rows of chain, a spreader bar,

and drag weights.

For more information about Leaf Spring, Abbey machinery, rotary hoes for sale, effluent disposal and Harrow NZ wide visit our website or feel free to contact us now.

Monday, 27 September 2021

Choosing the Right Tank for the Task

There are a variety of factors that are taken into account when choosing a slurry tanker and one can feel overwhelmed when choosing one when there is an array of models, makes, and accessories involved.

Slurry tankers are best if you want to spread

effluent nutrients over the farm. There are a lot of different things that you

will need to keep in mind before you choose the right make and model to suit

your needs. FarmGard NZ stock a variety of Abbey tanks that could be perfect

for your needs, however, it’s important to have a solid understanding of your

requirements to ensure you end up with the perfect piece of equipment.

In this blog, we’ll take you through a guide on how

to choose the right tank for the task.

One of the most important things that you should

consider in the tanker is the size. Generally speaking, the bigger the better;

you don’t need to be conservative when it comes to this feature. So, how can

you choose the right size? Well, it depends on four factors that are discussed

below:

Tractor Size

The size of the tractor will determine how much

much is safe to pull. Generally, you should be able to handle at least 100L per

HP. This is just a general guideline and factor that needs to be considered.

Note down your requirements and continue reading to learn about the other

factors that need to be considered such as braking axles on the tanker and

topography.

Topography

If you live in a hilly area, you should first

consider the safety and risk of rollover. Due to hilly landscapes, the liquid

tends to move from side to side, this means stability becomes vital as do the

brakes! If gravity is greater, you should go for a smaller size. However, for

flatlands, a larger sized tanker is a safe option.

Infrastructure

Small farms have smaller gateways and narrower

races which can potentially limit the size of the tanker you can opt for.

However, if you have good driving skills and good steering axles, this might

not be an issue for you but for seasonal and less experienced drivers, this is

something to be considered.

Moreover, anyone with advanced tractor skills can

easily handle the job and reap all benefits of owning a slurry tanking.

Furthermore, bear in mind that not only gateways

and tracks are needed to be considered, your farm sizes, the quantity of

effluent disposal to be shifted and the amount of storage are all factors that hold

great importance. In terms of both labour and cost efficiency, the fewer trips

you need to make the better.

Investment

While the investment cost is important, it’s more

important to first determine the size of the tanker you really need to make the

most of the investment. Getting the right size can end up saving you time and

money, where getting something too small can end up costing more in labour and

maintenance. More loads = more time + higher wear and tear. It should

also be noted that the running costs of a slurry tanker are generally about the

same regardless of size.

Friday, 20 August 2021

A Guide About Purchasing a Lawn Mower

Unpowered reel mowers

Corded Electric Lawn mower

Petrol mowers

Ride-on mowers

Thursday, 8 July 2021

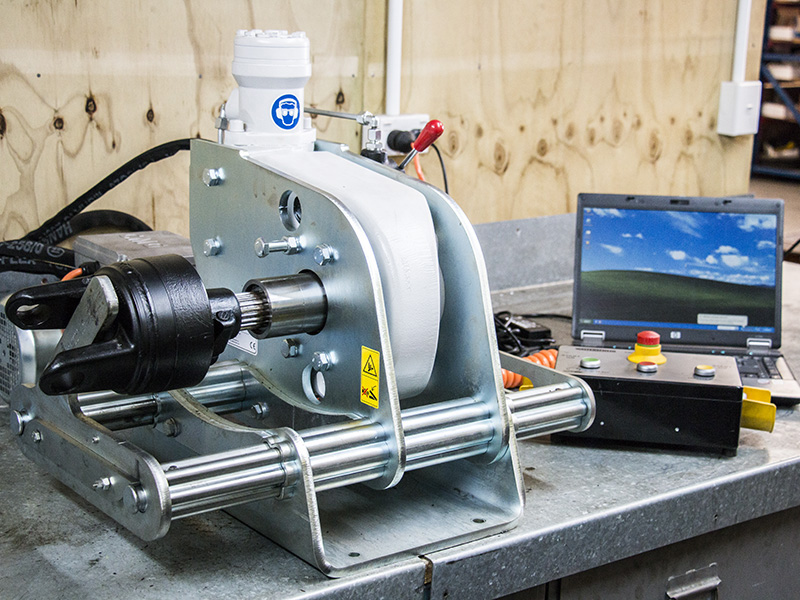

A Guide About Clutch Testing

You can use the steps in this post regularly to maintain your clutch and to get a clearer idea of the faults, wear, and tear that your components might have. These steps are crucial if you have a second-hand car that has clocked a lot of miles. Well, let’s get straight to the point, here are some of the steps that you can follow:

Start with a Basic Check

The best thing to do is start with a basic check, especially if you aren’t satisfied with your components and don’t have time to go to the shop. Switch on the car and put it into gear while pressing the clutch continuously.

If you notice strange noises or grinding, then you should further check where the issue is. Keep an eye on the signs, the clutch could be slipping, this happens when the clutch doesn’t engage properly. If there is hesitation in the engine slightly, or in extreme cases, your car may rev excessively while driving.

Drive and Test the Clutch Operation

If step one was successful, a test drive is the best way to check the functionality of the clutch a little further. Start by pulling off in first gear, as you would usually do. When the clutch is released, if it shows signs of abnormal behaviour, especially if it starts to make strange noises, you may well have a problem that needs to get looked at. The clutch may be worn out and will need to be replaced sooner rather than later.

Pulling Away in a Higher Gear

If you’ve completed the aforementioned tips and don’t see an issue, it is time to try something out of the box. All you need to do is to stop the car normally and put it into third gear. Now attempt to pull away with this gear while balancing the pedal with the clutch to eliminate any chance of the car stalling.

Generally, the car will pull a lot slower as compared to the first gear but it should result in the car pulling away. If you see any signs of slippage or unusual sounds, the only thing to do is to turn off the car right away and call on a mechanic to replace the clutch or repair it.

Weighing Up Your Replacement Options

The steps outlined in this blog should have provided you with sufficient knowledge about the health of your clutch. If you’ve completed the steps and there haven't been any issues, but are still unsure, call an expert to get a second opinion. It’s always better to be safe than sorry! On the other hand, if you see issues while performing the steps, then the last step is to weigh up your replacement options. Make sure that you go to a reputable shop to get things perfect again and functioning. For more information about clutch testing, rotary hoes for sale and spreaders, visit our website now.

Wednesday, 7 July 2021

Importance of Clutch Testing

Traditionally all cars were made to be manual and with the evolution of technology, nearly all cars you see on the road these days are automatic. However, on the farms and in the agricultural business most of the vehicles come across are manual. Where manual transmission is concerned, the clutch holds great importance and without it, you are going nowhere.

Proper care of the clutch is crucial and clutches

that are maintained properly can last up to 130,000 km or more, on the other

hand, a clutch that is abused will start to fail after approximately 50,000 km

or less.

The clutch is important and clutch testing needs to be done

to make sure everything runs smoothly and so you don’t have to face hefty

maintenance costs. In this blog, we will try to help you understand what causes

the clutch to fail and how to overcome or avoid it.

Causes of Clutch Failure

Malfunctioning of Slave Cylinder or clutch master

cylinder:

A clutch master cylinder is responsible for holding

the brake fluid. This cylinder is connected to the slave cylinder through

hoses. When the clutch is depressed, the brake fluid moves from the master to

the slave where the pressure is applied to engage the clutch.

Both master and slave cylinders have seals that

wear out which causes the leak. The leak is then responsible for the clutch

malfunctioning. Common signs of master or slave cylinder failure include going

all the way to the floor and not being able to shift gears.

Leak in Clutch Fluid:

Clutch fluid is brake fluid. When a leak occurs in

the system it makes it hard to change gears causing the clutch pedal to go all

the way down to the floor. Also, there may be a puddle of brake fluid on the

floor of the garage. The sign of a fluid leak is just a glimpse and it can lead

to serious issues for your vehicle.

Slipping of Clutch:

While clutches are designed to slip a bit when it

first engages or when the gear is changed to provide a smooth ride but when it

is fully engaged there should not be any slippage at all. In many cases, the

slipping can happen when hauling a load or when inclining up a hill.

When slipping occurs, the clutch becomes hot,

resulting in the burning of clutch facings that can potentially damage the

pressure plate of the flywheel. A further potential consequence of clutch

slippage is wear tears. When you see this kind of issue, it needs to be

addressed as soon as possible to avoid additional damage to the vehicle.

Clutch Does Not Release:

There are so many things and factors that lead to

the clutch releasing problem. Everything in between the damaged input shaft

splines to a bent clutch disc to a worn-out bearing retainer. If a vehicle’s

clutch isn’t releasing it should be inspected or tested as soon as possible

because if not, it may lead to serious issues.

Hard Clutch:

A tanks hard clutch is another sign that your clutch

isn’t well. If you experience that your clutch is hard or stiff, it is better

to keep in mind that there is an issue with the pedal linkage or the clutch

cable.

These are some of the problems that occur, and some

of them can lead to serious issues. So, you need to check the clutch properly

regularly for a smooth operating vehicle.

Friday, 25 June 2021

Everything you Need to Know About Mulch

What is Mulch?

Rubber Mulch:

Bark Mulch:

Hardwood Mulch:

Hemlock Mulch:

Leaf Mulch:

Lava Rock Mulch:

Red Mulch:

Thursday, 27 May 2021

Grader Blade Techniques and Tips for Operators

Even if you are a professional operator, manager, or a new operator, here in this blog we will share some useful tips and techniques that will come in handy. So, let’s get started.

Top tips and techniques for motor grader operators

In order to get great efficiency, achieve durability, here are some useful tips and techniques for the operators of motor graders.Avoid wear and tear

Due to harsh and rocky terrains, your motor grader may face wear and tear. To avoid this, the operator needs to carefully and safely handle the equipment to prevent any unnecessary damage to the equipment. When using it, it should be kept in mind that only a required amount of downward pressure should be exerted and applied by the operator as if excessive pressure is exerted on a dry hard surface, it can cause wear in rapid cutting edge and the equipment will also consume more fuel and horsepower which ultimately reduces productivity.Correct moldboard positioning

You need to make sure the moldboard is correctly positioned. It is important and the operators need to straighten up as when rolling the blade of the grader forward to make the edge blunt.Keep the blade sharp

To keep the motor grader blade sharp, operators should ensure the blade is kept just forward of the cutting edge. This is done so that the blade only cuts forward when it is necessary.Change the right angle

You or any other operator should alter the blade angle periodically. In case you choose to keep the moldboard forward, it might result in wear at the front of the cutting edge.The right angle holds great importance and you have to consider the angle as per the material like for free-flowing and light material, moldboard angles around 10-30 degrees and when processing wet and sticky material or mixing or ditching large windows, the angles used on moldboard should be higher, around 30-50 degrees.

Beware of gutters and curbs

In the case when grading is done along with curbs and gutters, the operators need to pay extra attention because if any type of error occurs, it may result in the machine running against the curb and the edge chipped. Also, in such cases, the moldboard may be highly affected.Moreover, when ripping or sacrificing across a slope, the operators should keep the moldboard parallel along the front axle, lowered to the ground and centred to the frame in order to provide protection against them rolling over.

Lower the teeth

Every time when using the ripper, the operators need to make sure that the teeth are lowered into the ground with the grader. In case the rear wheels lose traction, the operator of the equipment should raise the ripper first until the wheels of the mower machines regain traction. This needs to be done when the Abbey machine is being used on hard surfaces. Also, the number of teeth should be reduced.The teeth under the pavement should be lowered to break the old pavement and also the ripper should be raised when lowering teeth. For more information about clutch testing, rotary hoes for sale and spreaders, visit our website now.

Wednesday, 12 May 2021

Mixer Wagon Maintenance

Vertical Mixer Owner Notes

- It takes at least a 450

cubic foot mixer to grind up a 5 x 6 bale of hay

- It takes around 8 minutes to process a bale of

alfalfa – longer for grass hay, cornstalks are similar to alfalfa

- A single screw vertical

mixer will unload faster than a twin screw because you have to wait for

the feed to get from the back of the mixer to the front

VERTICAL MIXER MAINTENANCE:

Plow blade

- The plow blade is the piece

of metal on the back of the screw. On the new

Pentas it is bolted on and it is welded on in most other wagons - Make sure the plow blade is not wore and is a

¼ “ from the side wall

- Even though the plow blade

looks like a small piece of metal (it is not along

for the ride so to speak) it is a very important piece of the puzzle for fast

and proper mixing action

Mixer Knives

- Check to make sure your

knives are not dull if you are cutting a lot of hay or

roughage (especially dairy) - If you are not worried about your knives and

do not do a lot of cutting, check to

make sure your bolt heads are not worn to the point where your knives

will fall off. This can cause major damage. - How far your knives can go

before you replace them depends on your application. So, if you are

confused give Farmgard a call.

Discharge

- Make

sure you have proper chain tension on the conveyor chain (3?of slack)

and the hyd. motor drive chain (normal roller chain tight)

Planetaries

- Make sure you have no leaks

- Make sure the oil level is at the proper

intervals

- If you haven’t changed your oil in 2000 hours

you should change it

- 2 speed oil every 1000 hrs.

Reel Mixer Owner Notes

- Red frame knights are older

than yellow frame knights

- A 2 spider reel is newer than a 3 spiral reel

- A 2 spider reel takes a high

roughage ration better than a 3 spider reel

REEL MIXER MAINTENANCE:

- Take a look in your wagon

and make sure your reel bars are not thin (especially where the

bolt and the reel spring is). We have seen reel bars get so thin, break

off, and then get stuck and cause auger damage.

- Check your gearbox for proper chain

tension and there aren’t any tensioner springs broken. This is a common

problem when we trade wagons in.

- Make sure your bearings (set

screws) are nice and tight on the augers and shafts.

Auger Discharge Owner Notes

- Make sure your drive chains

are tight

- Make sure your augers are not worn

- Make sure your auger bushings are not worn

badly

- Make sure your orbit motor is not leaking

Improve your Farm Operations With a Mower

Mowing is a basic yet effective farm maintenance practice that has numerous advantages in the management of orchards and vineyards. More spe...

-

When it comes to purchasing a slurry tanker, there are a lot of aspects to consider, and it's easy to get overwhelmed when there are so ...

-

The motor grader is a piece of equipment that is used widely at construction sites. From the motor grader blade to any other part, everythin...

-

Mowing is a basic yet effective farm maintenance practice that has numerous advantages in the management of orchards and vineyards. More spe...